Our analysis of the FA24 oil sump.

Our analysis of the FA24 oil sump.

FA24 Sump Design:

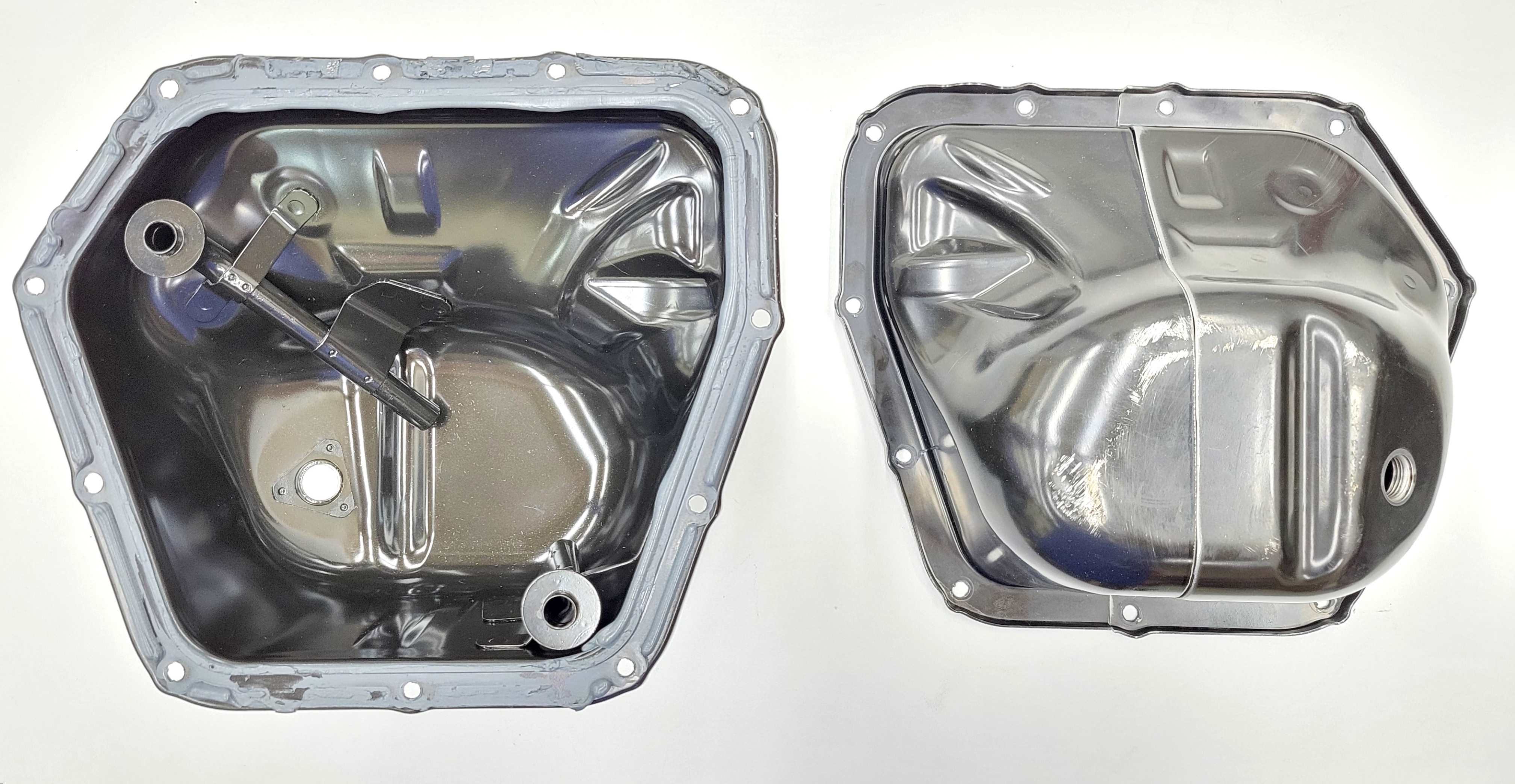

The FA24’s engine design uses a 2-piece sump design. The lower piece is made from stamped steel, has no baffle, and holds less than half of the engine’s oil capacity.

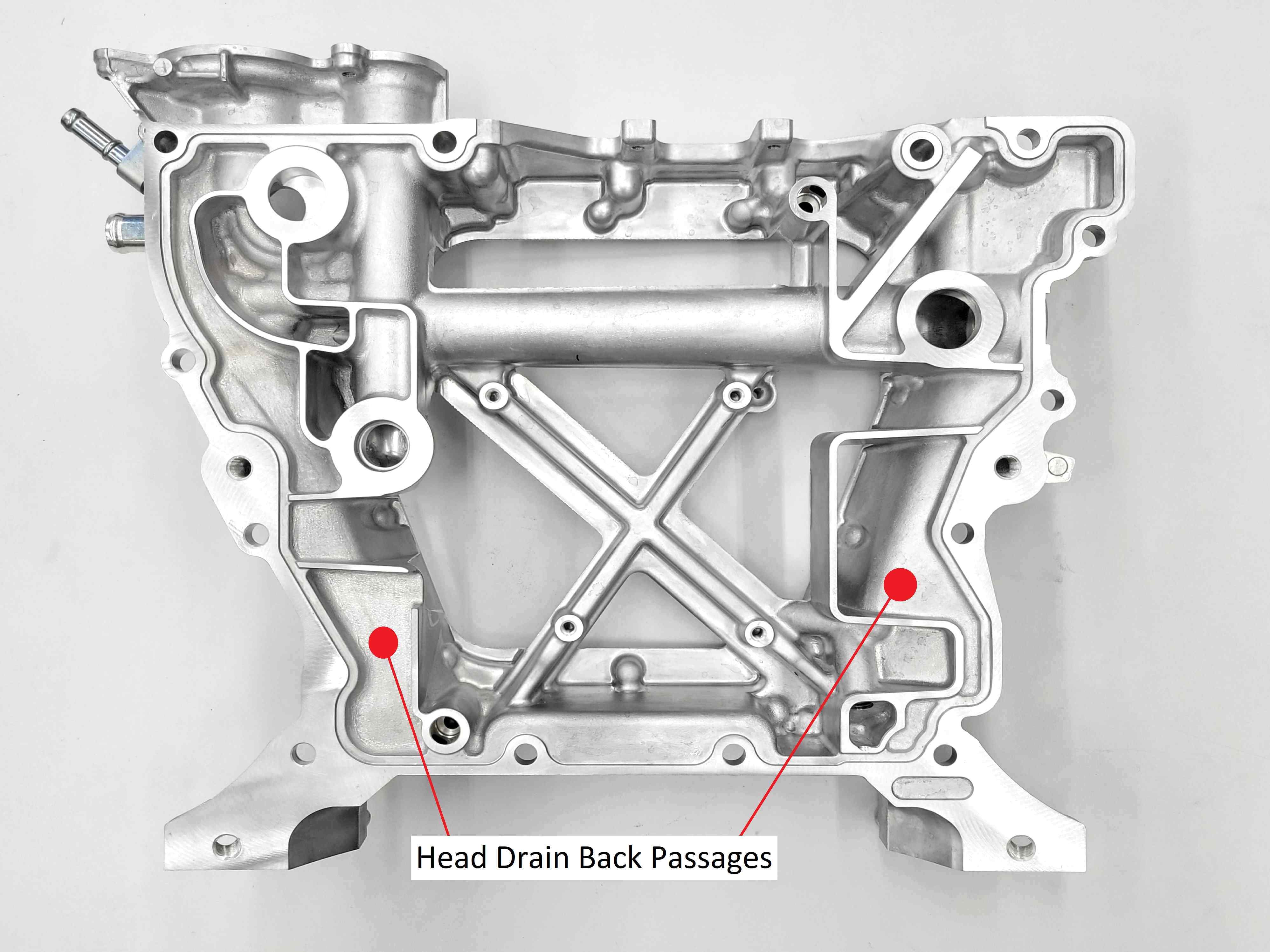

The upper piece is made from cast aluminum, has oil drain-back accommodations for the rear of each head, a flat plate baffle near the crankshaft to reduce aeration and reduce crankshaft induced turbulence that can impact PCV, and holds most of the oil. The drain backs are baffled, unlike previous Subaru engines that have head drains that were open to the sump. This is a good step forward in improving oil control; oil surge back-feeding into the heads during cornering.

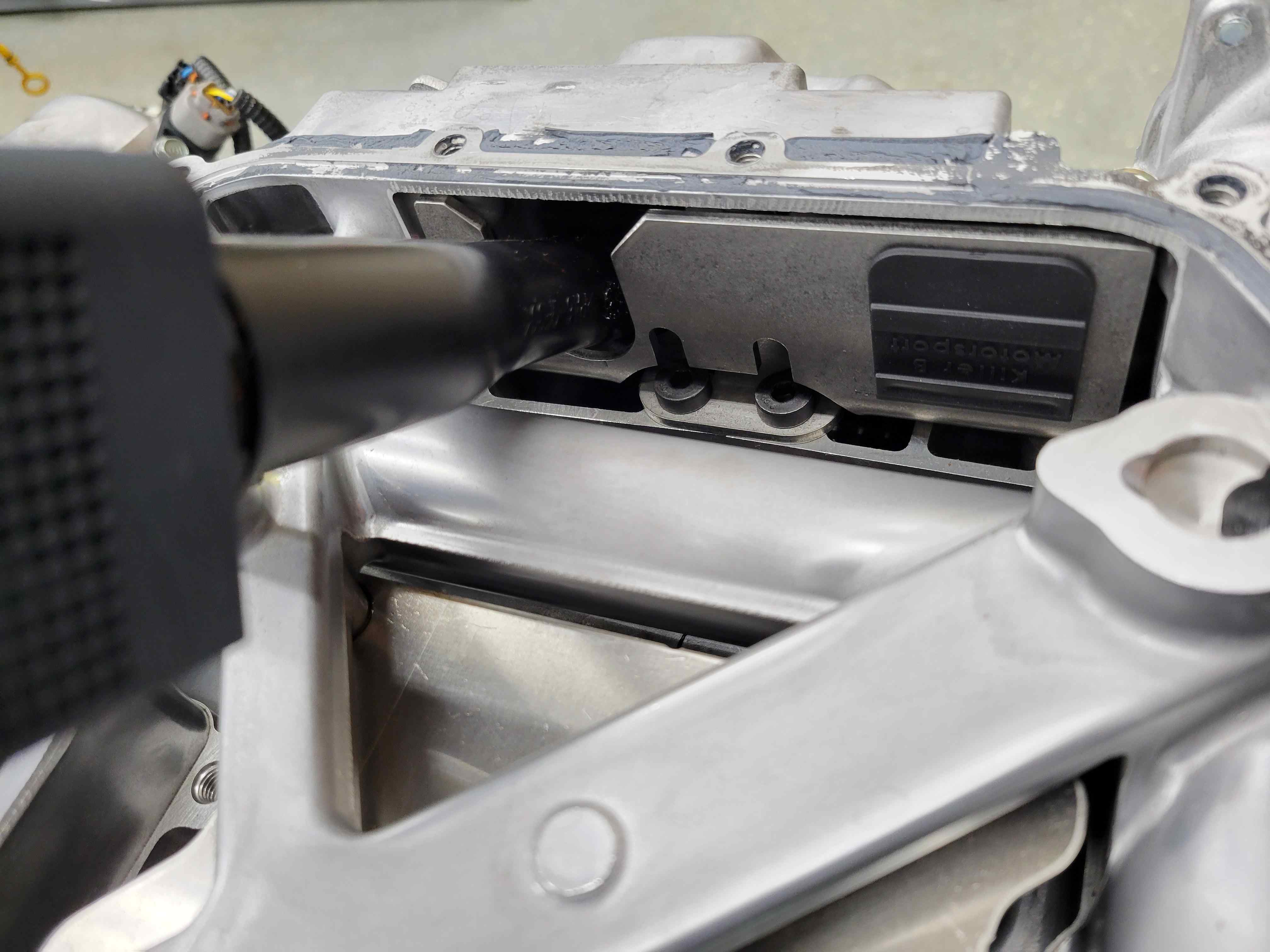

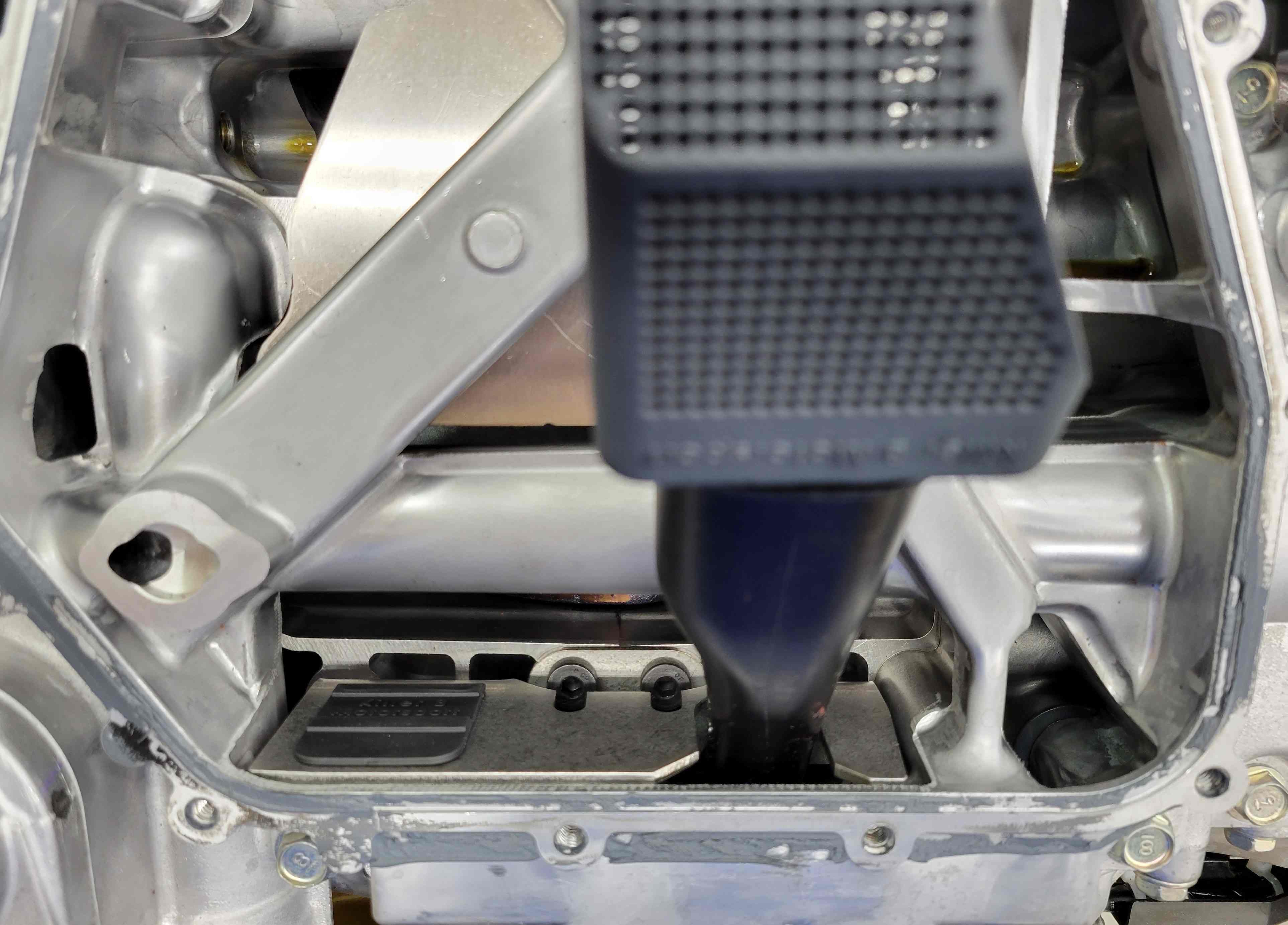

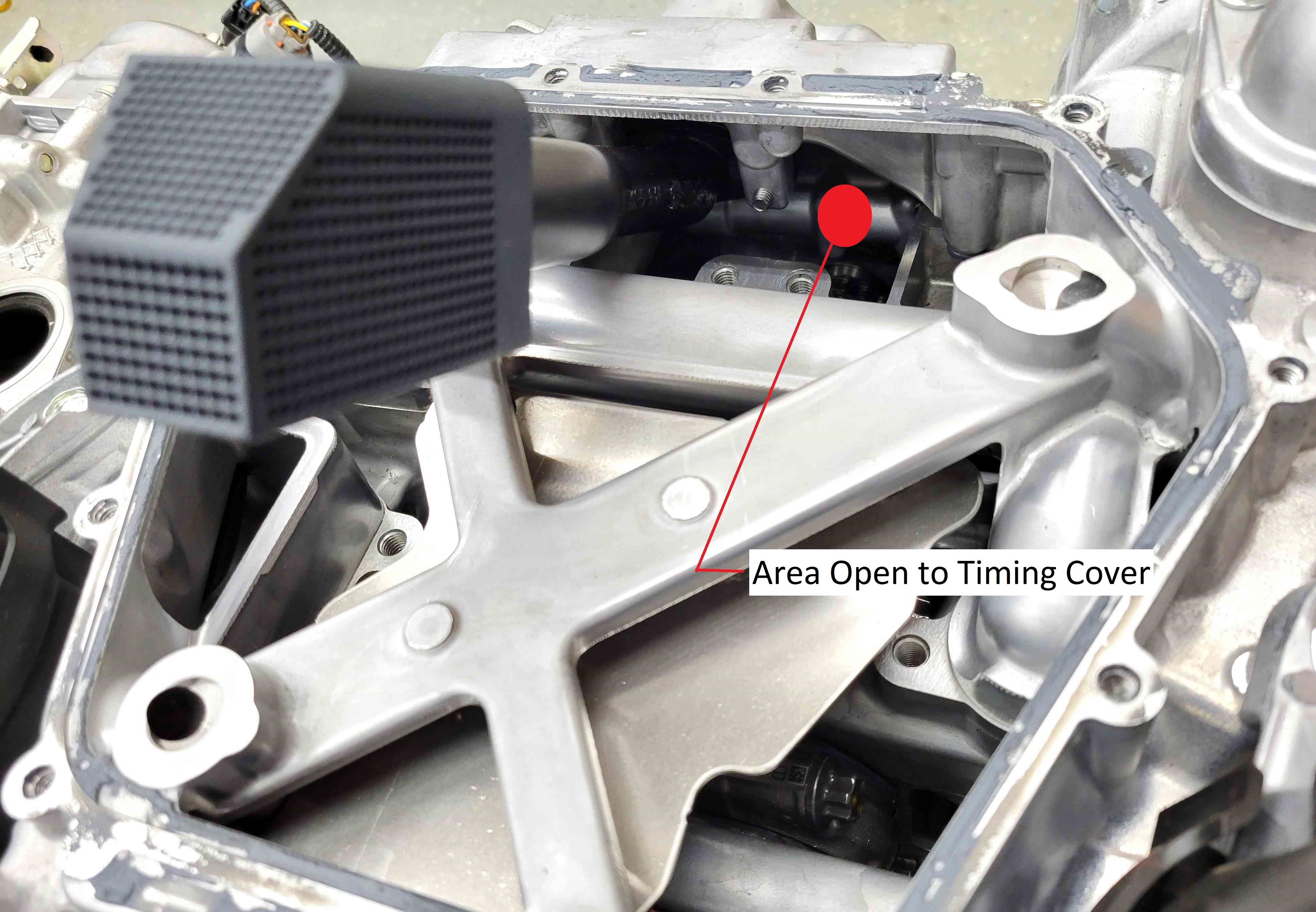

The engine’s Timing Cover is attached to the front of the engine and upper sump. It is a large piece with a lot of open area. There are some PCV provisions, and there are no baffles or other features to control the oil. There is a large opening from upper sump into the timing cover. The argument could be made that the timing cover is also part of the ‘sump’ because any amount of oil above the minimum level dipstick dot, is also held in the timing cover.

Hypothesis:

In motion, oil in the sump is dynamic. Oil is flowing off the crankshaft, from the drains in each head, and moves around via slosh or surge as acceleration and lateral forces change. The lower sump has a shallow wedge shape at the front. This shape makes it very easy for oil to ramp forward and upward into the upper sump and into the timing cover cavity. Oil from the heads drain from the bottom of each head into the upper sump, through some ‘baffle’ features. ‘Baffle’ features because these are not specific baffle components but cast in design features that create direction changes in the same manner as a baffle. While not perfect, this is a decent advance from previous Subaru engines where the head drains were unobstructed from oil slosh causing backflow into the heads. The timing cover is a large open space that contains the cam timing components, sprockets, and chain. The sides of the timing cover have low spots that trap oil. Under high RPM the chain can rope oil causing more oil to be drawn from the sump area as well.

Theory of Operation:

Any slow-down caused by throttle lift or braking causes a significant amount of oil to surge into the timing cover reducing oil level in the sump. With a cornering motion following, the oil in the timing cover then moves into the side of the timing cover and will stay there until the end of the corner and acceleration resumes.

The Killer B Motorsport Oil Retention Baffle restrict oil from freely flowing into the timing cover, thereby increasing the level available in the sump. A one-way flap valve allows any oil that does flow into the timing, easily able to flow back into the sump as acceleration resumes.